Hey, it’s way past time for another post that’s actually about natural dyeing. Many of you know that I’m not doing much dyeing right now, but I’m still knitting with plenty of natural dyed yarn. I recently pulled a 50/50 cotton/wool blend out of my stash that had been languishing there for a while – it’s a nice wheat color that I always loved, but I guess didn’t have good skein appeal. I pulled it after carrying it to too many shows, and last week got inspired to start knitting a loose summery sleeveless wrap.

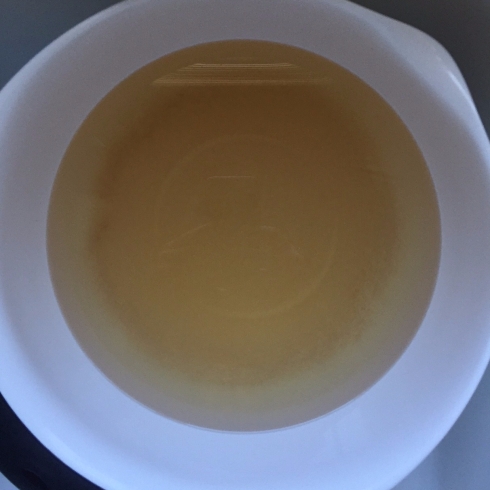

I knit a panel and blocked it by soaking it in slightly warm water with a little Eucalan. Here’s what the water looked like after soaking:

I knit a panel and blocked it by soaking it in slightly warm water with a little Eucalan. Here’s what the water looked like after soaking:

You might be thinking – hmmmm. Or even – whoa! That’s a _lot_ of color washing out. And it’s true, that’s what it looks like, and it’s not surprising that you might jump to the conclusion that the yarn is bleeding like a stuck pig and it wasn’t dyed properly. But let’s wait for a few hours and look at that rinse water again:

Can you see that there’s fine silt lining the sides of the bowl? It looks like something has settled out of the water. What’s going on here? Because I’m the one who dyed the yarn, I can actually tell you.

This yarn was dyed with fustic, which is a wood. I use raw dyestuffs, so I buy fustic chips and boil it several times to create a dyebath.

Fustic wood chips

You can see that the wood chips are mostly small flakes – thin so they wet out and extract nicely. And there’s also a bit of fine sawdust in there too, check out the bottom of the bag:

Check out the fine sawdust

The sawdust also wets out and extracts nicely. But what happens after you’re done with extracting the dye? Now you have 5 gallons of hot water with wood chips floating around in it – if I stuck nice fluffy wool yarn straight into that, it would immediately be full of chips. So I filter. And then I filter again. And then I filter even more.

Good filters are a dyer’s best friend

I’ll typically go through 3-4 stages of filtering before the dyebath is ready for yarn – one large strainer to get most of the large material out, then a 220 micron filter to remove sand-sized particles, then a 75 micron filter to remove fine coffee-ground-sized particles, then a 43 micron filter to remove as much of those fine silt-like particles as I can. This is my least favorite part of dyeing with raw dyestuffs. It’s physically demanding – hoisting and slowly pouring 5 gallons of liquid over and over – and it’s a little dangerous because the water has recently boiled and is still quite hot. I do wait for it to cool after the first filtering stage, but I usually need to get something else going in that pot. It’s also slow. If I try to hurry and skip filtering steps, it takes even longer because the filters clog.

Even after all of those filtering steps, there’s still some degree of fine wood particles left in the dyebath, you’ll never get every one out. Which means that some will get picked up in the yarn. Some fall out when the yarn dries. Some fall out during ball winding – this tends to leave a layer of fine particles on your table that isn’t usually apparent until you wipe it off with a damp paper towel. Some fall out during knitting, which is usually only noticeable if you wear lotion. You may see a streak of color on your fingers, where the yarn has run across them. And some still remains in the yarn, and falls out when you wash it. Let’s look at the wash water again – I scooped some water off the top of the bowl with the wine glass and you can see it’s almost clear.

When I slowly poured the water off, this is what’s left behind:

So, it’s totally normal for naturally dyed yarns to still have fine particles of the dyestuff in them, and to appear to bleed when you wash them. Your yarn won’t lose color and it won’t lighten. It also won’t contaminate another color, though I always recommend knitting and blocking a swatch first. Especially if you’re thinking of doing a complicated colorwork project with high contrast, make sure it washes well before you have an orange sweater instead of a red & yellow striped one.

This is what a swatch looks like.

That covers wood-based dyes, and the same is true for flower and leaf-based dyes. Weld especially has very fine pollen that creates a fair bit of silt. Though indigo is a different beast entirely (which I’ve talked about in this silly video) the crocking mechanism is actually pretty similar to what I’ve been discussing in this post. Solid particles get stuck in your yarn, then get loose. With indigo, the main difference is that the particles are even smaller and are pretty much how the dye works in the first place.

Before going on to the last type of dye – animal dyes like cochineal – I’m going to digress and talk about extraction. It’s very important for natural dyers to get the most out of each dyestuff. They’re expensive! Way more expensive than synthetic dyes, so in order to compete in a market that is dominated by synthetic hand-dyed yarn, and only price your yarns a few dollars higher, you have to be really thrifty with getting the most out of every dyestuff. It is not uncommon for natural dyers to have $2-$5 of pure dye cost in each skein. And of course, the cost varies according to the dye. And it can vary by time of year – it’s like food. Sometimes a particular fruit is bountiful and sometimes it’s not. Sometimes there’s a drought that affects the entire supply. Sometimes fashion and food trends impact demand and suddenly send dye costs skyrocketing. This happened to cochineal around 2009 – the price increased by 600%. Politics and war can also play a part – Afghanistan used to grow a good amount of high quality madder, and now much of that has been replaced by opium.

For cochineal in particular, I boil it several times, using the first extraction for reds and pinks, while the second extraction goes to lighter shades of pinks, or purples by saddening with iron or copper mordants. I still have 6 containers of once and twice-boiled cochineal in my freezer, waiting for me to dye something else with it. This may make me sound like a crazypants dye lady, and no, there are no more inedible dead animals in my freezer, but this is what cochineal retails for. If you grind up 1 oz of high quality cochineal, it’ll dye about 4 skeins of yarn. Maybe 2 skeins if you’re going for a really bright fuchsia. And sometimes the quality isn’t as good and you need to use more.

OK, so now that you understand why extraction and getting the most out of dyes is so important, I’ll go back to cochineal preparation. I buy whole dried cochineal bugs. You can boil them whole, but they don’t extract as well as ground bugs do. I grind cochineal in a burr-style coffee grinder on a coarse setting, put it in cheap pantyhose, and boil it. The reason I contain it in pantyhose is that it takes forever to filter if I don’t. I made the mistake just throwing the ground cochineal into water once, and it was a never-ending filter clog – I’d pour out a quart, the filter would clog completely, I’d pour it back into the unfiltered pot, rinse the filter, repeat. I can’t tell you how frustrating that kind of problem is, or how much it actually costs a dyer. If you spend an hour babysitting a filter like that, you’ve just lost money on that batch of yarn. You can’t indiscriminately boost the price of a few skeins because it took you longer to dye them, and sometimes you wouldn’t be able to charge enough to actually cover your time on a troublesome batch.

So pantyhose does a reasonable job of containing the ground cochineal, but it’s not perfect. There are still a couple of filtering stages, and there are still going to be some fine solid bits. Cochineal also seems to be the one natural dye that does legitimately tend to run more than the rest. It’s not considered as washfast as some of the other natural dyes, though it’s fine for the typical hand-washed life of a hand knit. I’d recommend washing any cochineal-dyed yarn in cold water, go very very light on the soap, and don’t soak it for very long. Set a timer for 5 minutes, just enough to fully wet the yarn and clean the garment. In contrast, cochineal is one of the best dyes in terms of lightfastness, so go wear that hat in all the direct sunlight you want.

But what about dyers who use extracts? Will their yarn still have fine particles in it? Yes, it will. Extracts are not perfectly 100% soluble, there’s almost always a tiny bit that remains solid. It also depends on the dye, for example, I hear that madder tends to have more insoluble bits.

Well, I hope you’ve learned a bit about natural dyes and what to expect in terms of washing. Good natural dyers will go through several wash steps before the yarn is dried, skeined, labeled, and sold to you. But no matter what, you’ll probably see some color in the wash water (more so when the dyer uses raw dyestuffs!), and that’s OK.

But what if it’s not OK? What if it’s really running a lot and you actually ARE losing color? Contact the dyer. No matter how careful we are, there are a ton of variables that influence natural dyeing, and despite our best efforts, it’s impossible to fully control them all. Sometimes shit just happens. No dyer wants you to be unhappy with their yarn, and they do want to know about problems. Send them a calm and collected email, explain what’s happening, and find out what you or they can do about it. If you’re not cool and collected because it took you 2 years and 5 million tears to knit this fucking sweater which is now NOT the color the yarn was in the skein…..well, that sucks, but maybe now you understand why swatching AND blocking your swatch is so important. Still contact the dyer, but maybe have a drink and good night’s sleep first, especially if that dyer is me. :)

xo, and happy knitting with natural dyes!

-Carrie